Yearly worldwide carbon dioxide (CO2) emissions reached 34.2 gigatonnes (Gt) in 2019, with transportation accounting for about 25% of total CO2 emissions. With worldwide energy demand expected to rise by at least 50% by 2050 owing to population expansion and accompanying increases in energy consumption, large-scale deployment of low-carbon renewable energy (RE) is required to mitigate environmental consequences by reducing anthropogenic CO2 emissions. According to recent analyses, a complete transition to 100% RE is achievable over the next three decades or so with a cost-effective vision of comprehensive electrification of the global heat and transportation sectors. Yet, one of the most important enabling features for the RE future is the ability to store and move RE on a multi-exajoules (EJ) scale to regulate the energy system.

Hydrogen (H2) is a possible energy vector for efficient use in fuel cells (FCs). While liquid H2 (LH2) has the benefit of being easily converted into gaseous H2, the liquefaction procedure wastes almost 30-40% of the energy content of H2 in addition to boil-off losses during transit. To avoid the inherent problems with LH2 storage and transmission, various alternative carbon-based fuels, including methanol (CH3OH), methylcyclohexane (MCH), and ammonia (NH3), have been suggested as more technically feasible choices, owing to their desirable qualities.

In contrast to LH2, NH3 is readily liquefied by raising the pressure to 10 bar at ambient temperature or cooling to 33 °C under 1 atm. Moreover, because of its low vapour pressure and high boiling point, NH3 is safe to store and transport. When the lower heating value (LHV) of H2 is taken into account, the volumetric energy density of NH3 (12.92-14.4 MJ/L) is similar to that of MeOH (11.88 MJ/L) but substantially greater than that of MCH (5.66 MJ/L) and lithium-ion batteries (0.9-2.63 MJ/L).

With developed NH3 production, storage, and transportation infrastructures, NH3 has been identified as a potential H2 and energy carrier for both mobile and fixed applications. With a worldwide production capacity of 230 million tonnes (Mt) per year, NH3 is now the second most manufactured chemical in the world. Today, 180 Mt of NH3 is generated yearly, mostly using the steam methane reforming (SMR) method to create the required H2, followed by industrial NH3 synthesis. NH3 has an annual market value of $70 billion. NH3 is mostly employed in the fertiliser sector but is also used in refrigeration, cleaning, and metal treatment.

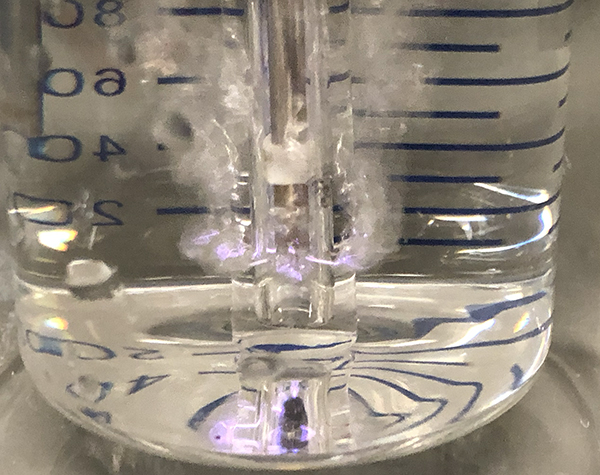

In conclusion, although traditional ammonia manufacturing technologies such as steam methane reforming (SMR) are energy-intensive and generate considerable quantities of glasshouse gases, attempts to create low-temperature electrochemical NH3 synthesis have shown promise. Nevertheless, the present productivity rate must be greatly raised for practical use. On the other hand, hybrid plasma electrocatalysis has shown a substantially greater output rate by activating nitrogen through a non-thermal plasma before the electrochemical process. The scalability and dependability of this technique and related approaches for green ammonia production need to be studied. Further research and development are required, particularly in financing such ventures. Governments must play an essential role in promoting the development of sustainable ammonia production technologies since private investments may not align with the technology’s level and the long-term advantages it may give.

References:

https://doi.org/10.1021/acsenergylett.1c02189

https://doi.org/10.1021/acsenergylett.2c01615

Taking the forefront in the movement towards a sustainable energy future through the implementation of eco-friendly ammonia and hydrogen solutions.