A team of researchers from the University of Sydney and The University of New South Wales (UNSW) in Australia have collaborated on a project to develop a more sustainable method for water Disinfection.

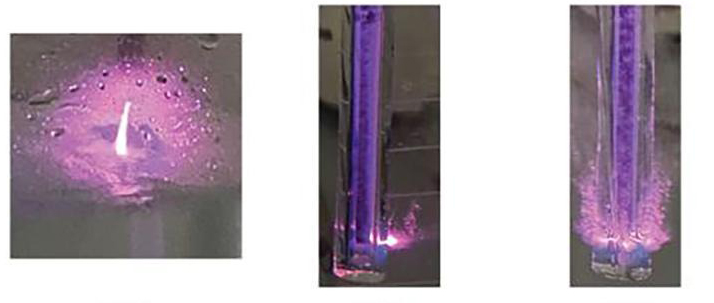

In recent years, plasma-activated water (PAW) has emerged as an effective and cost-efficient disinfectant for various applications, including environmental remediation, food decontamination, and irrigation. PAW is produced by the interaction between non-thermal plasma and water. A new study has proposed a hybrid plasma discharge (HPD) reactor for the generation of PAW. This reactor produces two simultaneous plasma discharges from the high-voltage electrode and the ground electrode, enclosed in a quartz tube. The design of the reactor induces high electric fields around both electrodes, resulting in an efficient inactivation of bacteria.

The HPD reactor is studied to increase the production of reactive oxygen and nitrogen species (RONS) and improve the energy efficiency and the antibacterial efficacy of PAW, while increasing the liquid volume. The study evaluated the effect of input voltage, orifice size, number of orifices, and liquid salinity on the performance of the HPD reactor. The results showed that the HPD reactor achieved a high RONS energy efficiency and a high inactivation against Escherichia coli.

The proposed HPD reactor can be used in the agriculture, biomedical, food, and water treatment industries to produce PAW in larger volumes, while minimising the energy consumption. The study highlights the potential of PAW to offer economic and environmental benefits due to its simple operation and potential to be easily integrated with renewable electricity. PAW can also provide an alternative to conventional decontamination techniques that pose adverse environmental impacts and may cause product quality loss.

In conclusion, the HPD reactor developed in this study showed promising results in the efficient production of PAW with high antibacterial efficacy. Further studies are required to evaluate the potential of PAW for other applications and to optimise the design of the HPD reactor for industrial-scale PAW production.

The results are published at Chemical Engineering Journal Volume 451, Part 2, 1 January 2023, 138643. https://doi.org/10.1016/j.cej.2022.138643